PERFORMANCE

SPECIFICATION 3 - SPECIFICATIONS AND TEST PROCEDURES FOR O2 AND CO2 CONTINUOUS

EMISSION MONITORING SYSTEMS IN STATIONARY SOURCES

2.0 Summary of

Performance Specification.

8.0 Sample Collection,

Preservation, Storage, and Transport.

8.1 Relative Accuracy

Test Procedure.

9.0 Quality Control.

[Reserved].

10.0 Calibration and

Standardization. [Reserved]

12.0 Calculations and

Data Analysis.

13.1 Calibration Drift

Performance Specification.

13.2 CEMS Relative

Accuracy Performance Specification.

14.0 Pollution

Prevention. [Reserved]

15.0 Waste Management.

[Reserved]

17.0 Tables, Diagrams,

Flowcharts, and Validation Data. [Reserved]

1.0 Scope and Application.

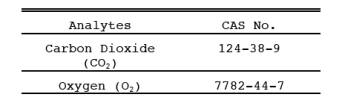

1.1 Analytes.

1.2 Applicability.

1.2.1 This

specification is for evaluating acceptability of O2 and CO2

continuous emission monitoring

systems (CEMS) at the time of installation or soon after and whenever specified

in an applicable subpart of the regulations. This specification applies to O2 or CO2 monitors that are not included under Performance

Specification 2 (PS 2).

1.2.2 This

specification is not designed to evaluate the installed CEMS performance over

an extended period of time, nor does it identify specific calibration

techniques and other auxiliary procedures to assess the CEMS performance. The

source owner or operator is responsible to calibrate, maintain, and operate the

CEMS properly. The Administrator may require, under Section 114 of the Act, the

operator to conduct CEMS performance evaluations at other times besides the

initial test to evaluate the CEMS performance. See 40 CFR Part 60, Section

60.13(c).

1.2.3 The

definitions, installation and measurement location specifications, calculations

and data analysis, and references are the same as in PS 2, Sections 3, 8.1, 12,

and 17, respectively, and also apply to O2 and CO2 CEMS under this specification. The performance and equipment

specifications and the relative accuracy (RA) test procedures for O2 and CO2

CEMS do not differ from those for

SO2 and NOx CEMS (see

PS 2), except as noted below.

2.0 Summary of Performance Specification.

The RA and

calibration drift (CD) tests are conducted to determine conformance of the CEMS

to the specification.

3.0 Definitions.

Same as in Section

3.0 of PS 2.

4.0 Interferences. [Reserved]

5.0 Safety.

This performance

specification may involve hazardous materials, operations, and equipment. This

performance specification may not address all of the safety problems associated

with its use. It is the responsibility of the user to establish appropriate

safety and health practices and determine the applicable regulatory limitations

prior to performing this performance specification. The CEMS users manual

should be consulted for specific precautions to be taken with regard to the

analytical procedures.

6.0 Equipment and Supplies.

Same as Section 6.0

of PS2.

7.0 Reagents and Standards.

Same as Section 7.0

of PS2.

8.0 Sample Collection, Preservation, Storage, and Transport.

8.1 Relative Accuracy Test Procedure.

Sampling Strategy for reference method (RM) Tests, Correlation of RM and CEMS Data, and Number of RM Tests. Same as PS 2, Sections 8.4.3, 8.4.5, and 8.4.4, respectively.

8.2 Reference Method.

Unless otherwise

specified in an applicable subpart of the regulations, Method 3B or other

approved alternative is the RM for O2 or CO2.

9.0 Quality Control. [Reserved].

10.0 Calibration and Standardization. [Reserved]

11.0 Analytical Procedure.

Sample collection and

analyses are concurrent for this performance specification (see Section 8).

Refer to the RM for specific analytical procedures.

12.0 Calculations and Data Analysis.

Summarize the results

on a data sheet similar to that shown in Figure 2.2 of PS2. Calculate the

arithmetic difference between the RM and the CEMS output for each run. The

average difference of the nine (or more) data sets constitute the RA.

13.0 Method Performance.

13.1 Calibration Drift Performance Specification.

The CEMS calibration

must not drift by more than 0.5 percent O2 or CO2 from the reference value of the gas, gas cell, or optical filter.

13.2 CEMS Relative Accuracy Performance Specification.

The RA of the CEMS

must be no greater than 1.0 percent O2 or CO2.

14.0 Pollution Prevention. [Reserved]

15.0 Waste Management. [Reserved]

16.0 References.

Same as in Section

17.0 of PS 2.